What is Rigid or Hard UV LED Ink?

Rigid or Hard UV LED ink is an ink that is applied directly to a substrate or print medium. The term “Rigid” or “hard” refers to the type of substrate the ink is intended for. Rigid/Hard UV LED ink will not stretch or bend well. Often, the ink will crack under strain. Rigid/Hard UV LED ink is best for rigid/hard substrates because while not flexible, the ink has incredible adhesion properties and extremely high abrasion resistance. Rigid/Hard UV LED ink can be used for both indoor and outdoor products.

Rigid or Hard UV LED inks work better on rigid/hard substrates, especially those that are more difficult to print on as they adhere faster and stronger. Below is a list of rigid/hard materials and the suitable primers to be used with them for better ink adhesion.

1.: For glass especially – This is for overall page.

2.: For acrylic especially – This is for overall page.

3.: For stainless/AL related/iron/metal water proof / glass water proof – This is ONLY for spot page.

4.: For metal/stainless/mdf/AL related/Iron/Ceramic – This is for overall page.

What is the difference between hard and soft UV ink?

The soft ink has stronger pressure resistance and ductility: soft ink can make UV inkjet printer spray on the soft material, and in the case of material distortion, there will be no faults or cracking. When using hard inkjet printing, the graphic pattern will crack when the material is distorted.

What is UV LED Curable ink?

UV LED curable inks are a type of ink that remains a liquid until it is cured with an ultra-violet light. In general UV LED curable inks are desirable because they produce vivid colors, can be paired with an ink primer to guarantee longer adhesion, and high abrasion resistance. UV LED Curable inks come in hard and flexible varieties.

Rigid UV LED Ink (Hard)

A Rigid or hard UV LED curable ink refers to the ability to stick to non-pliable substrates including glass, stainless, coated metals, plastic, PVC sintra, acrylic, wood, coroplast, foam board and more.

Benefits of the Printers Media Plus, LLC UV LED Rigid inks:

- Exceptional adhesion properties

- Extremely high abrasion resistance

- Fast dry time

- Results in bright and vibrant colors

- Can be used indoors and outdoors

The Advantages and Disadvantages of Rigid/Hard UV LED Ink

The ability for rigid/hard UV LED inks to dry quickly as well as the added durability it provides makes it ideal for pieces that are subject to such conditions that may provide for scratching and exposure to chemical solvents. Another benefit of rigid/hard UV LED ink is that it produces very bright and vibrant colors, which can make it the perfect choice for printing large graphics and photos where the colors need to pop.

While rigid/hard UV LED ink is beneficial for many applications, there are some disadvantages. Rigid/Hard UV LED ink is not flexible. It will crack if the substrate is stretched or bent too much. Flexible UV LED ink would be more suitable.

Flexible UV LED Ink (Soft)

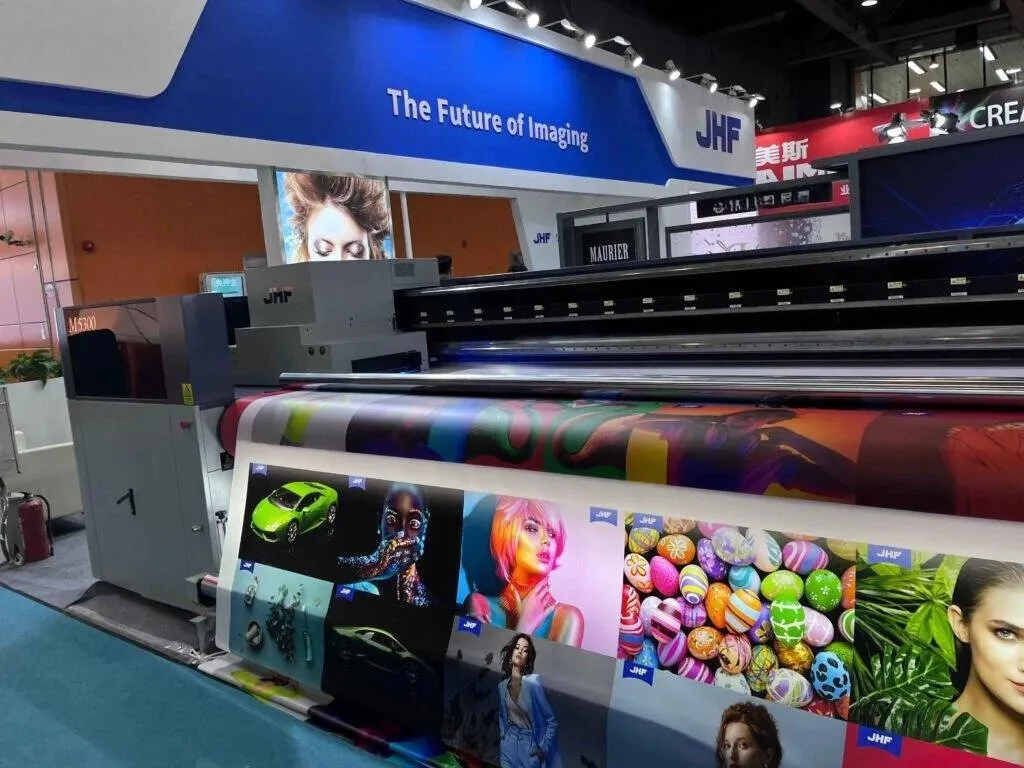

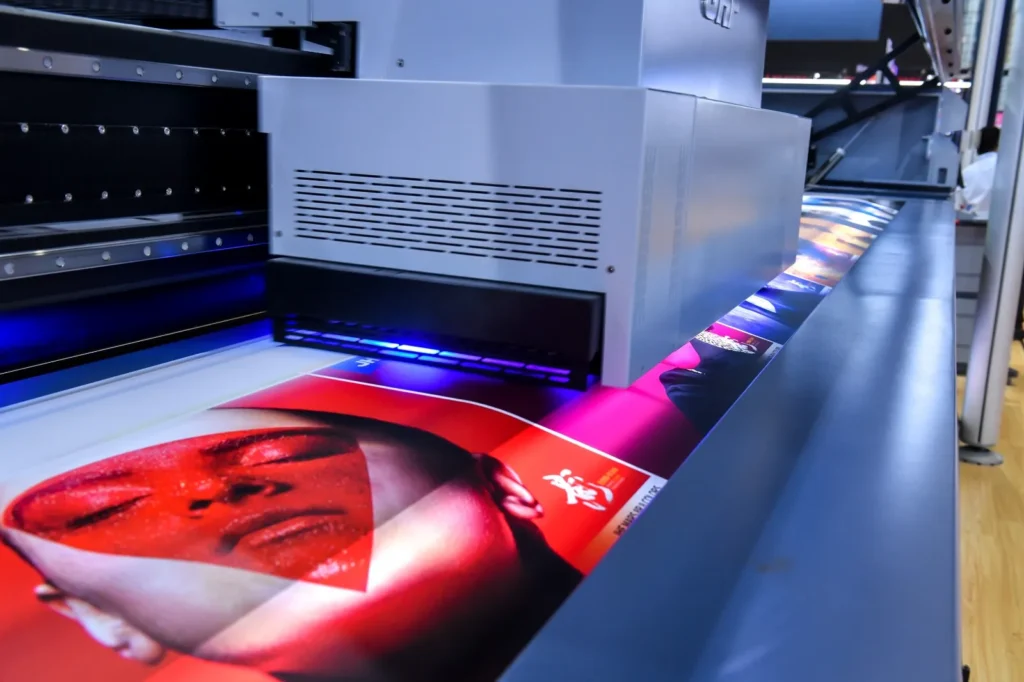

A flexible UV LED curable ink is used with a wide format Roll to Roll UV LED digital inkjet printer like the JHF V398 to print on rolls of flexible media such as PVC banner, self-adhesive vinyl, mesh banner or mesh fabrics, backlit media, One Way Vision and other flexible printing media used at print shops and sign shops.

Benefits of the Printers Media Plus, LLC Flexible UV LED Ink (Soft):

- Flexible!

- Can withstand freezing temperatures

- High weather resistance

Hybrid/Neutral UV LED Ink

Hybrid/Neutral UV LED ink is suitable for flexible/soft and rigid/hard materials. It can print on a variety of substrates including glass, stainless, coated metals, plastic, PVC sintra, acrylic, wood, coroplast, foam board, TPU, PVC banner, self-adhesive vinyl, mesh banner or mesh fabrics, backlit media, One Way Vision and more.

Our hybrid/neutral UV LED inks are made from premium raw materials and also provide excellent white coverage and color stability, ensuring the overall quality and long-term beauty of your prints. Our UV LED digital inkjet printer ink exhibits excellent yellowing resistance after light curing.

Superior Formula, Perfect Adhesion, No Discoloration, No Stickiness

Printers Media Plus’s rigid/neutral UV LED inks are specially formulated for the roll to roll, hybrid and flatbed printers. This gives our UV LED ink perfect adhesion after printing. After light curing, our UV LED ink will not change color or become sticky.

Good Balance, Suitable for Printing on Rigid/Hard and Flexible/Soft Materials – Suitable for Printing on More Than 75% Of Materials.

Printers Media Plus’s hybrid/neutral UV LED inks feature excellent balance and you have the flexibility to choose rigid/hard and flexible/soft materials as bases.

High Color Concentration and Bright Color Performance

Whether it is advertising works or artistic works, Printers Media Plus’s rigid/neutral UV LED ink provides users with professional printing effects with its high color density and vivid color performance.

Environmentally Friendly, Low Odor, Free of Toxic and Volatile Organic Solvents, And Compliant with VOC Emission Standards.

Printers Media Plus, LLC provides you with environmentally friendly and safe solutions. Our rigid/neutral UV LED inks are environmentally friendly, low odor, non-toxic formulas and contain no volatile organic solvents.