Specially formulated to print on rigid or flexible media, JHF OEM Flexible, hybrid and rigid UV LED inks broaden the scope of possible applications. This is what you can expect:

Say goodbye to forklift upgrades. We understand that a high-volume UV inkjet printer is a strategic investment for your business, what you do not want is to have to replace it when your business needs change before you have amortized that investment. As your business grows, your strategy needs to evolve to suit changed circumstances. With the JHF Series of UV inkjet printers, you can either grow your business by upgrading to a higher level of productivity, or you can tune your JHF UV inkjet printer to your growing business needs. The entry level unit can be upgraded to a variety of different configurations. Depending on your applications, your customers’ demands or your business plans, you can choose to upgrade different ranges of speed and or functionalities and features. Upgrading is fast and efficient; we can install any of the upgrades in your premises and have you back and fully operational with your upgraded capacity, operational extremely fast. Here is an overview of the amazing range of possibilities that you can have with the JHF Series of UV inkjet printers.

The addition of light cyan and light magenta will expand your range of color gradations. You will be able to print more grey levels than before for more realistic, smoother skin tones and subtle degrades. Adding light cyan and light magenta enhances the print quality considerably, producing a more photo-realistic image. If high level art, fashion and cosmetics are your market, this is the upgrade for you.

Imagine being able to print on any flat object or media, regardless of base color. White ink capability offers a print shop owner the ability to sell high value, backlit graphics and window clings on rigid and flexible media. White ink also gives printers with flatbed printers the ability to create specialty applications on almost any media or object. Doors, wood, glass, plex-glass, tiles, stone, cardboard, metals – the list is endless. The JHF Series of UV hybrid printers allow you to run single white, pre- and/or post white according to your application. White ink printing – it’s real and it’s profitable, and if you print window graphics for retail, it’s a must-have capability.

The JHF Hybrid UV printers are built on a new robust steel framed platform with advanced magnetic linear drive motion technology to achieve the greater accuracy needed for accurate 3/6 Pico liter drop placement. Completely redesigned from the ground up, the JHF Hybrid UV printers include the latest in advanced digital encoders and magnetic linear drive motors to deliver unparalleled dot placement accuracy to match the quality the market needs today and with tomorrow in mind. The latest safety features and enhanced UV light screening makes the JHF UV Hybrid UV printers not just the most reliable, but the safest new partners for your business.

The new electronics platform on the JHF Hybrid UV printers is designed for the future. With processor upgrade capability the JHF Hybrid UV printers have the power to keep your system running at top speed into the future. This power is not just for imaging, the JHF Hybrid UV printers also feature automatic head height adjustment so as you switch substrates, they adjust as well with no loss of time.

Protect the printheads from inadvertent strikes. Anti-static reliable printing – many rigid media are susceptible to static charge. This needn’t be a worry with JHF Hybrid UV printers’ anti-static system. Mounted right on the carriage to pass over your media before jetting, both negatively and positively charged areas of your media are neutralized, giving you worry-free results year-round.

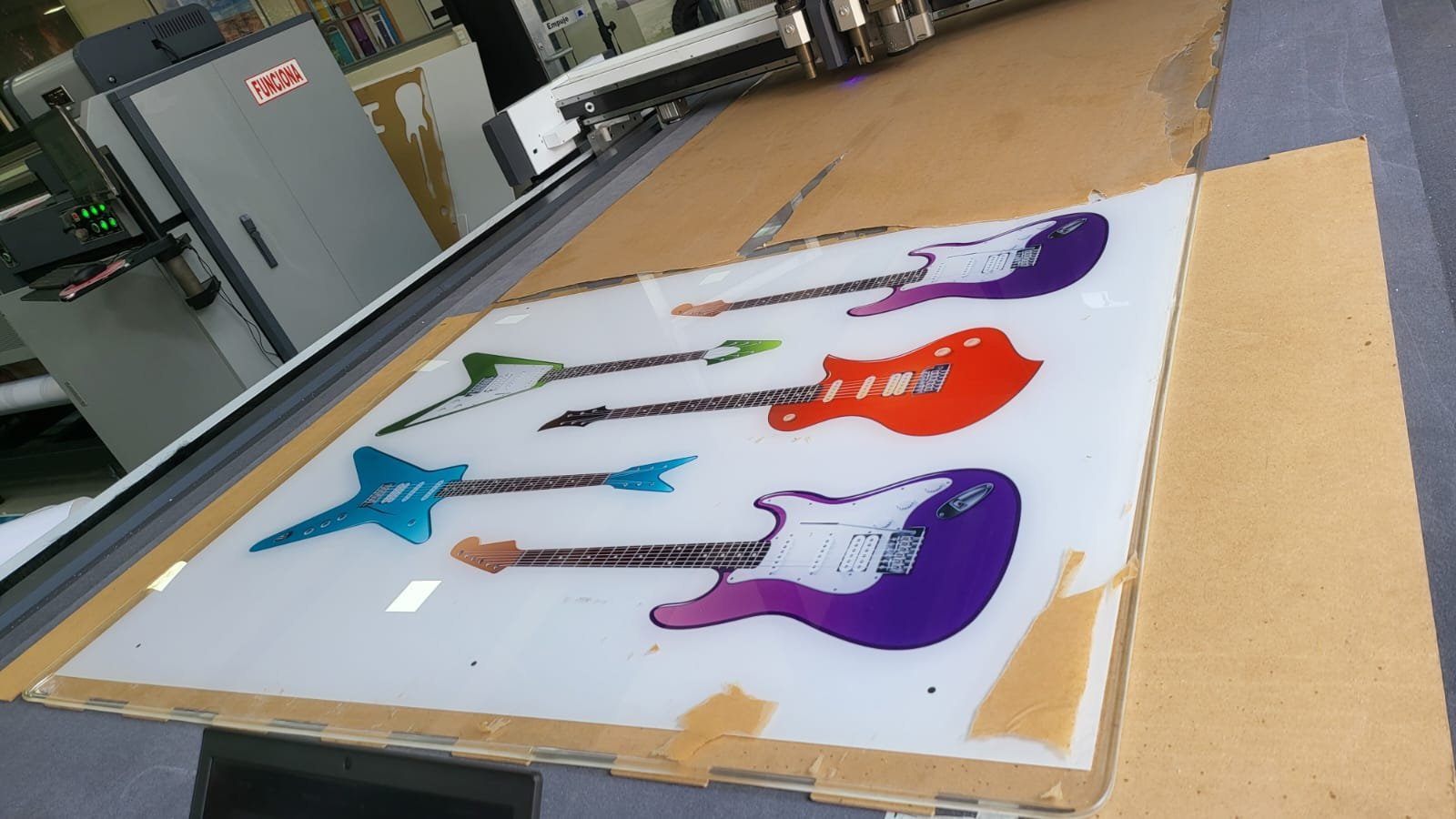

With the JHF Hybrid UV printers, you can print multiple boards simultaneously, saving time and boosting productivity. Print three 60 x 40-inch boards side by side at the same time. Retractable register pins help the operator to position the rigid material perfectly in place, accurately and consistently board after board. The flatbed architecture can print anything flat up to 4.7 inches (12cm) thick with a maximum dimension of 3.2m x2.00m.

389 Rider Ave, Bronx, NY 10451