First of all,

Linear direct drive motors have zero backlash, reducing settling times close to zero. Next to that, linear motors are not sensitive to mechanical inertia as there is no transmission, which enables extremely high dynamic performance.

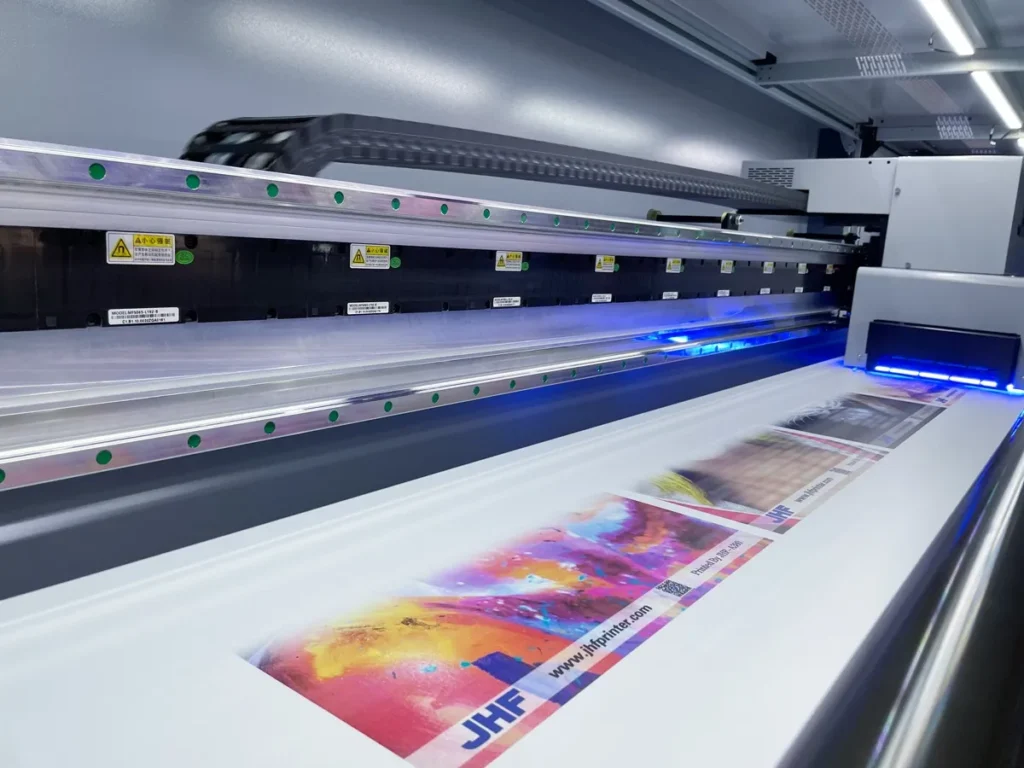

Our JHF wide format UV LED digital inkjet printers use a Linear-driven printhead carriage.

The JHF wide format UV LED digital inkjet printers are fit for extreme workloads. JHF equipped them with additional print heads and strengthened the beam and the magnetic drive linear motors for higher productivity or printing speed.

Magnetic Linear Drive Motor System

The JHF Linear Drive wide format digital inkjet series printers revolutionize the industry by using the advanced magnetic linear drive motor system to move the print carriage at speeds of 5 ft./second. The advanced magnetic linear drive motor system, along with the high performing Kyocera printheads in symmetrical array format (CMYK KYMC), allow for the highest quality and speed of any wide format UV LED digital inkjet printer in the industry. The JHF magnetic Linear drive motor system model comes in 126” Hybrid, 4×8′ Flatbed, 5×10′ Flatbed, 126″ Roll-to-Roll, and 196″ Roll-to-Roll options.

Increase printing speed and quality using magnetic linear drive motors

Linear Motor

The linear motor runs with the metal grating to ensure the high-speed, stable and accurate operation. Upgraded Linear Motor keeps high resolution, fast and stable printing. Plasma electrostatic eliminator improves stability when printing on static material.

Unmatched acceleration and dynamic movements

The direct drive technology of a magnetic linear motor is a perfect way to enhance productivity, accuracy, and dynamic performance. Direct drive motors eliminate the need for mechanical transmissions like rack and pinion, belts, and speed reducers. Between coil unit and magnets there is no contact, this means no mechanical wear. The technology makes designs slimmer, and modular and reduces costs.

Linear motors

Are also referred to as direct drive units since the load is directly coupled to the motor. This eliminates the need for elastic components such as gearboxes and couplings, which introduce backlash and error in the motion.

Because these motors do not rely on mechanical drive components such as ball screws, belts, and rack and pinions, linear motors have much higher accuracy and repeatability, with no velocity ripple.

This lack of rotating or recirculating parts also makes them virtually maintenance-free and contributes to a lower total cost of ownership when compared to traditional drive mechanisms.

The Benefits of Using Magnetic Linear Drive Motors for Wide Format UV LED Digital Inkjet Printers

Wide format UV LED digital inkjet printers have the advantage of using linear motors. Some customers have higher speed requirements. Generally, linear motors can be added on the original basis. Of course, it will be a little more expensive than ordinary ones, but there are many advantages.

1.: Only motors without gears, couplings or pulleys are needed to complete linear motion, which is of great significance for many applications. Those parts that are not important, reduce performance and shorten mechanical life are removed.

2.: Stable and reliable long life

3.: Simple structure

4.: High positioning accuracy

5.: Fast response

6.: New technology

7.: Using a higher performance magnetic levitation motor

Elevate Your Printing Game Today! Contact Us for Expert Solutions and Top-Notch Products!